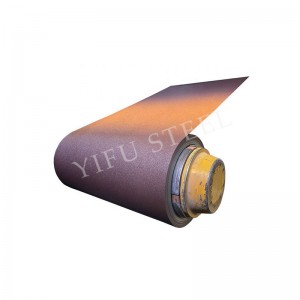

Feme e kholo ea kristale wrinkle/matt ppgi e koahetsoeng ka fektheri ea tšepe ea tšepe

1. Lintlha tsa sehlahisoa:

Boholo: 0.12-0.60mm * 30 * 1250mm

Mmala : 8019/5005/6020/8004//e le bareki'mehlala

Ho roala zinki: 40gsm

Bothata : bo tloaelehileng

2. ppgi matt/wrinkle steel coil ke eng?

E apesitsoeng ka mebalamatt/ wrinkletšepe ea tšepe ke e 'ngoe ea mefuta ea li-coil tsa tšepe tse koahetsoeng ka mebala.

sosobanacoil ea tšepe e bua ka tšepe e koahetsoeng ka mebala e koahetsoeng ka galvanized, galvanized, batang-rolled le substrates tse ling tse nang le sebaka se phahameng sa bolulo se hanyetsanang le boemo ba leholimo se nang le phello e phahameng ea ho hanyetsa mocheso holim'a metsi ka mor'a ho omisa.Haholo-holo e sebelisoa mokhabisong oa kahare le kantle oa meaho ea sechaba, li-villas, matlo a kopaneng a holimo, meaho ea indasteri, jj.

Lihlahisoa tse entsoeng ka ho khetheha tsa li-coil tsa tšepe tse koahetsoeng ka mebala li arotsoe haholo ka:

1. Coil ea tšepe e fetotsoeng e fetolang mebala

2. Mobala oa lijo-thollo oa lehong o koahetsoeng ke tšepe ea tšepe

3. Khoeli ea tšepe e sosobaneng e koahetsoeng ka 'mala (mokhoa oa lehlabathe / mohlala oa suede / mohlala oa lekhapetla la lamunu)

4. Pearlescent e koahetsoeng ka tšepe ea tšepe

5. Mobala oa matte o koahetsoeng ka tšepe ea tšepe

3. Mokhoa oa ho hlahisa :

Uncoiler —— Stitching Machine —— Barrels —– Tension Machine —— Uncoil —— Alkali le ho hlatsoa le ho degreasing —— ho hloekisa —— drying —— passivation —— drying —— primary coating —— ho omisa koae ea mantlha —— top coating —— top ho roala —— ho pholisa —— coil —— ho paka le ho bopa

4. Teko ea Sehlahisoa :

•Teko ea aberration ea Chronmatic

•Phapang ea mebala

•T koba teko

•Teko ea letsoai ea letsoai

•Tlhahlobo ea bokaholimo

•Teko ea ho ba letsatsing

5. Sephutheloana le thomello :

E 'ngoe le e' ngoe e se nang letho e tlameletsoe ka lihlopha tse peli ka leihlo la coil (kapa che) le circumferential e le 'ngoe.

Lintlha tsa ho ikopanya tsa lihlopha tsena moeling oa li-coil hore li sireletsoe ka litšireletso tse bohale.

Coil ka nako eo ho ka tsela e loketseng phuthetsoe ka metsi bopaki / manganga pampiri, e ka nako eo ho ba hantle le ka ho feletseng tšepe phuthetsoe.

Pallet ea lehong le tšepe e ka sebelisoa kapa joalo ka litlhoko tsa hau.(E tšekaletseng & E theohileng).

6. Lipontšo tsa lihlahisoa:

Rea u amohela ho etela k'hamphani ea rona !!!